Liquid Penetrant Test

Penetrant Testing Materials

The penetrant materials used today are much more sophisticated than the kerosene and whiting first used by railroad inspectors near the turn of the 20th century. Today’s penetrants are carefully formulated to produce the level of sensitivity desired by the inspector. To perform well, a penetrant must possess a number of important characteristics. A penetrant must:

- spread easily over the surface of the material being inspected to provide complete and even coverage.

- be drawn into surface breaking defects by capillary action.

- remain in the defect but remove easily from the surface of the part.

- remain fluid so it can be drawn back to the surface of the part through the drying and developing steps.

- be highly visible or fluoresce brightly to produce easy to see indications.

- not be harmful to the material being tested or the inspector.

What is penetrant?

This is a liquid. It has tha ability to penetrate or get into fine openings such as cracks.In terms of liquid penetrant inspection method, a penetrant is a liquid that has the ability to penetrate into every opening available to it. For inspection purposes, however, much more than the ability to spread and to penetrate the surface is needed.

PENETRATION MECHANISM

For good penetrant, only surface tension, wetting ability and viscosity have direct effect on penetrability (ability to penetrate)

Penetrability is the properties of a penetrant that causes it to find its ways into very fine openings, such as crack.

Physical Properties of Penetrant Materials

- Viscosity

- Surface Tension

- Wetting ability

- Specific gravity

- Volatility

- Flash Point

- Solubility

- Ability to spread or creep

- Tolerance to contaminants

- Toxicity

- Odour / Freedom from skin irritation tendencies

- Inertness or non-corrosiveness

- Washability

Theoretically, good penetrant shoud have :

- Good wetting ability

- very small contact angle

- High surface tension

- But, this is difficult to achieve – i.e. to have both high cos θ (small θ) and τ at the same time

- Surface tension in a liquid is an example of cohesive force, when the molecules are attracted to like

molecules. The cohesive force tends to bind them together. - Wetting action in a liquid is an example of the adhesive force, where the molecules are attracted to

foreign matter and the adhesive force tends to spread the liquid

Liquid penetrant inspection (LPI) is one of the most widely used nondestructive evaluation (NDE) methods. Its popularity can be attributed to two main factors: its relative ease of use and its flexibility. LPI can be used to inspect almost any material provided that its surface is not extremely rough or porous. Materials that are commonly inspected using LPI include the following:

- Metals (aluminum, copper, steel, titanium, etc.)

- Glass

- Many ceramic materials

- Rubber

- Plastics

All penetrant materials do not perform the same and are not designed to perform the same. Penetrant manufactures have developed different formulations to address a variety of inspection applications. Some applications call for the detection of the smallest defects possible and have smooth surfaces where the penetrant is easy to remove. In other applications, the rejectable defect size may be larger and a penetrant formulated to find larger flaws can be used. The penetrants that are used to detect the smallest defect will also produce the largest amount of irrelevant indications.

Type of penetrant

Penetrant materials come in two basic types. These types are listed below:

- Type 1 – Fluorescent Penetrants

- Type 2 – Visible Penetrants

PENETRANT SYSTEM

Penetrant systems are generally identified by the method of penetrant removal

- Water Washable

- Post-emulsified

- Solvent-removable

Three systems are common to both fluorescent and visible

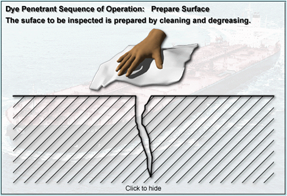

Surface Preparation

One of the most critical steps of a liquid penetrant inspection is the surface preparation. The surface must be free of oil, grease, water, or other contaminants that may prevent penetrant from entering flaws. The sample may also require etching if mechanical operations such as machining, sanding, or grit blasting have been performed. These and other mechanical operations can smear metal over the flaw opening and prevent the penetrant from entering.

One of the most critical steps of a liquid penetrant inspection is the surface preparation. The surface must be free of oil, grease, water, or other contaminants that may prevent penetrant from entering flaws. The sample may also require etching if mechanical operations such as machining, sanding, or grit blasting have been performed. These and other mechanical operations can smear metal over the flaw opening and prevent the penetrant from entering.

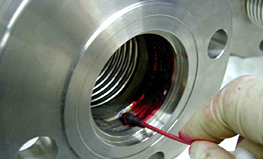

Penetrant Application

Penetrant Dwell

The penetrant is left on the surface for a sufficient time to allow as much penetrant as possible to be drawn from or to seep into a defect. Penetrant dwell time is the total time that the penetrant is in contact with the part surface. Dwell times are usually recommended by the penetrant producers or required by the specification being followed. The times vary depending on the application, penetrant materials used, the material, the form of the material being inspected, and the type of defect being inspected for. Minimum dwell times typically range from five to 60 minutes. Generally, there is no harm in using a longer penetrant dwell time as long as the penetrant is not allowed to dry. The ideal dwell time is often determined by experimentation and may be very specific to a particular application.

| Material | Form | Type of Discontinuity | Penetration Time min* |

|---|---|---|---|

| Brass & Bronze | castings | porosity | 10 |

| cold shuts | 10 | ||

| extrusions and forging | laps | 10 | |

| welds | lack of fusion | 10 | |

| cracks | 10 | ||

| all forms | cracks | 10 | |

| Magnesium | castings | porosity | 10 |

| cold sluts | 10 | ||

| extrusions and forgin | laps | 10 | |

| welds | lack of fusion | 10 | |

| porosity | 10 | ||

| all forms | cracks | 10 | |

| steel | castings | porosity | 10 |

| cold sluts | 10 | ||

| extrusions and forging | laps | 10 | |

| welds | lack of fusion | 20 | |

| porosity | 20 | ||

| all forms | cracks | 20 |

| Material | Form | Type of Discontinuity | Penetration Time min* |

|---|---|---|---|

| Aluminium | castings | porosity | 10 |

| cold sluts | 10 | ||

| extrusions and forging | laps | 10 | |

| welds | lack of fusion | 10 | |

| porosity | 10 | ||

| all forms | cracks | 10 | |

| Plastics | all forms | cracks | 10 |

| Glass | all forms | cracks | 10 |

| Carbide-tipped tools |

lack of fusion | 10 | |

| porosity | 10 | ||

| cracks | 20 | ||

| Titanium and High temp tools |

all | 20 or 30 | |

| Ceramic | all forms | cracks | 10 |

| porosity |